There are two types of knitting: hand knitting and machine knitting.

Hand-knitting uses stick needles. It has a long history, exquisite craftsmanship, and flexible flower shapes, which have been widely spread in folk.

Knitting production is divided into two categories: weft knitting and warp knitting.

In weft-knitting production, after the raw material passes through the yarn, the package yarn can be directly produced on the machine. Each yarn is sequentially laid on the knitting needles of the weft knitting machine in the weft direction to form a weft knitted fabric.

In warp knitting production, the raw materials go through the winding and warping, and the yarns are arranged in parallel and wound into warp beams, and then produced on the machine. The yarn is unwound from the warp beam, and each yarn is individually cushioned on one or at most two knitting needles of the warp knitting machine in the longitudinal direction to form a warp knitted fabric.

Weaving (weaving) can also be called "woven", using yarn as warp, weft to form a woven fabric according to various fabric structures. According to the type of raw materials used, it can be divided into cotton, wool, silk and linen, and their products are collectively referred to as woven fabrics.

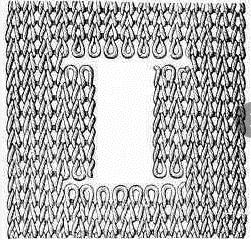

Knitted cloth is a fabric formed by using knitting needles to bend yarns into loops and twist each other. It is mainly divided into two categories: circular woven and flat woven fabrics (also known as warp knitted fabrics and weft knitted fabrics).

Due to the different weaving methods, knitted fabrics and woven fabrics have their own unique characteristics in terms of processing technology, fabric structure, fabric characteristics, and finished product uses. Here are some comparisons:

First, the composition of fabric organization

(A) Knitted fabric: A yarn is sequentially bent into a loop, and the loops are connected in series to form a fabric. The process of forming a loop of yarn can be performed horizontally or longitudinally. Lateral weaving is called weft knitting and longitudinal weaving. Called warp knitted fabric.

(B) Shuttle fabric: It is a fabric made of two or more sets of mutually perpendicular yarns interlaced at a 90-degree angle of warp and weft. The longitudinal yarns are called warp yarns and the transverse yarns are called weft yarns.

Second, the basic unit of fabric organization

(A) Knitted fabric: The loop is the smallest basic unit of knitted fabric, and the loop is composed of loop trunk and extension line in a spatial curve.

(B) Woven fabric: Each point of intersection between warp and weft yarns is called a weaving point and is the smallest basic unit of a woven fabric.

Third, the fabric characteristics

(A) Knitted fabric: It can stretch in all directions, has good elasticity, has large air permeability, and feels soft.

(B) Woven fabric: Because the warp and weft stretch and shrinkage of the woven fabric are not closely related, and no conversion occurs, the fabric is generally tight and stiff.

Fourth, the fabric characteristics

(A) Knitted fabric:

Because the loop is made by bending the yarn in space, and each loop is composed of one yarn, when the knitted fabric is subjected to external tension, such as longitudinal stretching, the loop bending changes, and the height of the loop also increases. The width of the loop is reduced. If the tension is stretched in the lateral direction, the situation is the opposite. The height and width of the loop can obviously be changed under different tension conditions, so the stretchability of the knitted fabric is large.

(B) Woven fabric:

Because the warp and weft yarns are intertwined, and they bend in a direction perpendicular to the plane of the fabric, the degree of bending is related to the mutual tension between the warp and weft yarns and the stiffness of the yarn. When the woven fabric is subjected to external tension, such as longitudinal When stretched, the tension of the warp yarn increases, and the bending decreases, while the weft yarn increases, such as continuous stretching in the longitudinal direction until the warp yarn is fully straightened, and the fabric shrinks horizontally.

When the woven fabric is stretched laterally by external tension, the tension of the weft yarn increases, the bending decreases, and the warp warp increases, such as the horizontal stretching is continued until the weft yarn is completely straightened, and the fabric shrinks longitudinally. Warp and weft yarns do not change, unlike knitted fabrics.

Five, the physical and mechanical properties of fabric

(A) Knitted fabric: the physical and mechanical properties of the fabric, including longitudinal density, transverse density, square meter weight, elongation, elasticity, breaking strength, abrasion resistance, curling, thickness, release, shrinkage, covering And bulk density.

(B) Woven fabric: The physical and mechanical properties of the woven fabric, including the yarn density of warp and weft yarns, selvedge, front and back, forward and reverse wool direction, fabric coverage

Angora goat hair, also known as Angora goat wool, is typical of long-gloss long wool, belo......

There are two types of knitting: hand knitting and machine knitting.Hand-knitting uses sti......

1.BarreFor knitted fabrics, this defect is characterized by the presence of uneven pattern......

Shrinkage is a phenomenon that changes the length or width of textiles in a certain state ......

1. Content of velvet:The down content is the amount of down in down. Generally speaking, t......

Fiber is the prerequisite for the development of textile products. The colorful textile pr......

An electrostatically charged object approaches or contacts another object, and as long as ......